Rooted from the start in the heart of our company, a culture of performance drives the growth and progress of AKWEL.

In all countries where the group is based, our performance involves standardisation of equipment, manufacturing processes, validation methods and factory management.

Our performance is measured in the everyday work of our expert teams, our continuous improvement initiative and our capacity to identify best practices and share them with all our plants.

Global presence

- 36 production sites

- 7 representative offices

See our international locations

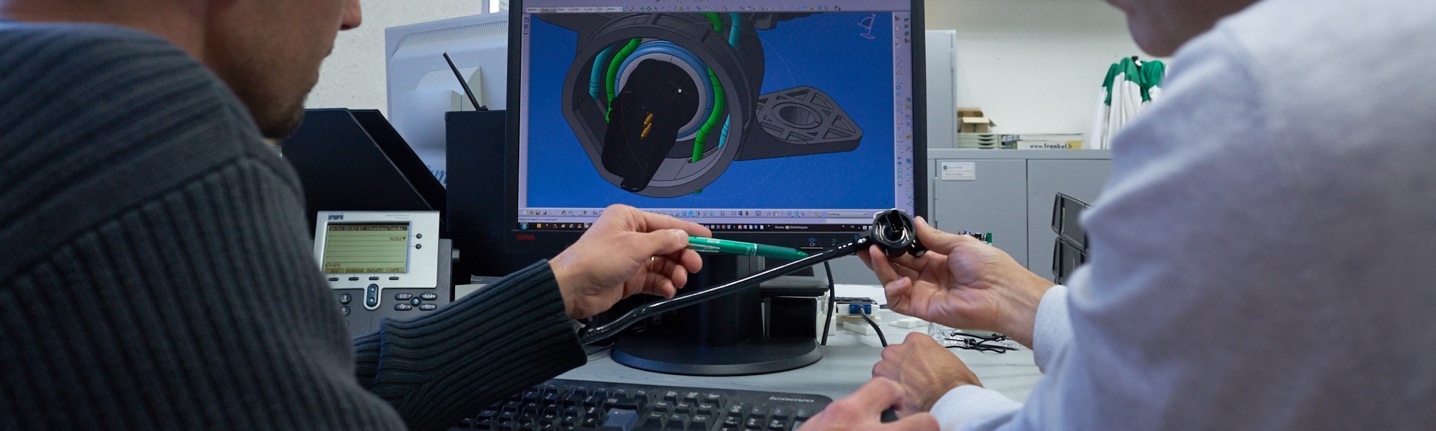

Innovation

- 138 patents lodged over the last 5 years.

We help our customers manufacture autonomous connected vehicles which are more reliable and more environmentally-friendly, at a competitive price.

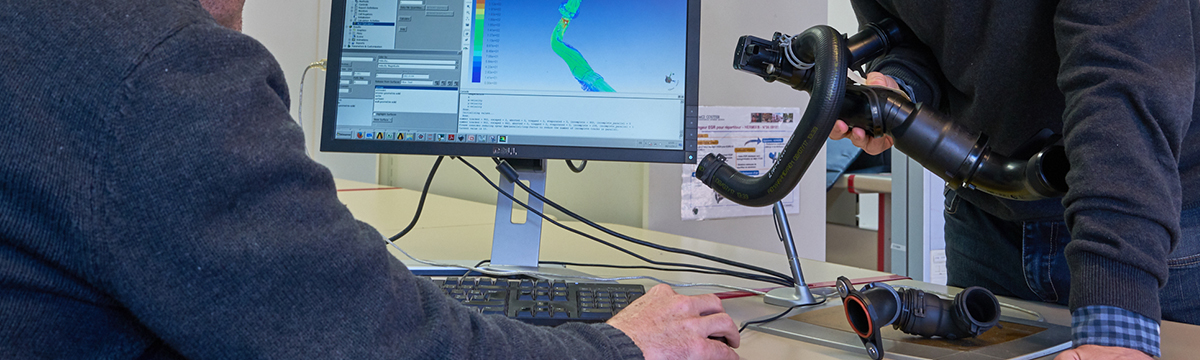

AKWEL offers a wide range of solutions for cooling, combining – among other products – pipes, valves or sensors. Our technical expertise and our multi-materials know-how (plastic, metal and rubber) mean we are able to provide our customers with global solutions adapted to all kinds of motorisation. Our skills in ventilation and cooling help us design products that meet the specific requirements of electric and hybrid vehicles.

AKWEL offers numerous technological solutions ensuring a reduction in the permeability of systems in order to respond to the changes in standards on all fuels. The integration of smart functions helps us improve engine efficiency, reduce pollutant emissions, and also assimilate and anticipate new regulations as well as possible.

Our fuel circuit know-how extends from filler necks to engine pipes, through under body pipes, flow regulation valves, anti-return valves, pulsation dampeners or temperature and pressure sensors.

Plastic or rubber, the AKWEL Group has developed specific know-how in managing negative pressure air for steering functions and brake assist functions. Connectors and valves enrich the function by complementing our product offering.

Capable of combining plastic, rubber and metal, we design and manufacture complete systems of complex pipes for air intake, meeting the strictest regulations. Air distributors, turbo air intake and output pipes and exchangers, EGR pipes (exhaust gas recirculation) … our solutions, the product of experience and innovation, make it possible to optimise engine performance, reduce the weight and overall dimensions of parts and ensure maximum energy management.

Cylinder head covers with particularly innovative integrated settling tanks contributing to reducing oil vapour emissions by twenty per cent, blow-by heating pipes and fittings, sealing … our range of solutions adapts ingeniously to the various configurations possible and responds, point by point, to the regulations currently in force.

We manage complete washer systems, from tanks to jets, including storage, pumping, transfer and jet.

Our systems are optimised in terms of weight, bulk and consumption, thus contributing to reducing CO2 emissions. Our systems are constantly evolving in order to meet the washer requirements of electric and self-driving vehicles.

We offer innovative solutions or concepts (reduction, additives systems) aimed at providing our customers and drivers with responses to environmental issues.

Our innovative additives systems (FAP, SCR, etc.) include electronic management of hardware (innovation, development, prototyping), software (development and validation), transfer, storage, reheating and pumping.

AKWEL’s know-how in mechanisms architecture can be seen in many areas (bonnets, boots, side doors, swing doors, etc.), whether for opening, closing or hinges. This is combined with an effort towards standardisation of our product to guarantee prompt marketing of the required parts. And lastly, our metal and plastic engineering means we can offer parts with perfectly optimised weight.